CAMDEN — By BRADLY GILL

Staff writer

The symbiotic relationship between Highland Industrial Park and SAU Tech has brought about many educational opportunities for students and the workforce. The Workforce Initiative Grant has provided a total of $1,942,170 to the college to develop programs that lead to jobs in the park. Now, a program previously only available as part of workforce training will make it’s way to the classroom side.

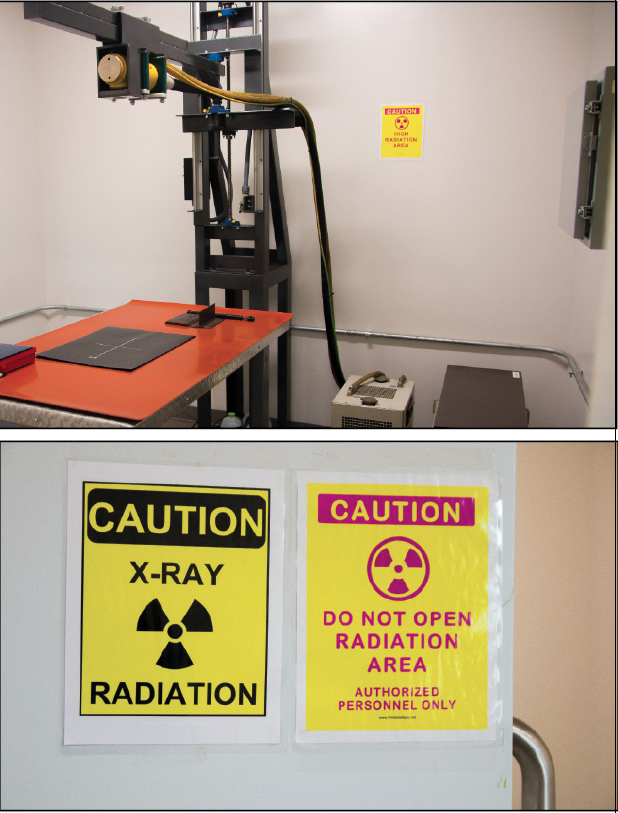

Non destructive testing (NDT) is a technique in which materials are tested but not destroyed. NDT is vital for constructing and maintaining all types of components and structures. To detect different defects such as cracking and corrosion, there are different methods of testing available, such as X-ray - where cracks show up on the film - and ultrasound - where cracks show up as an echo blip on the screen.

The method is similar to conventional radiography, but images are not captured on film. Instead, images are captured using either flat panel detectors or phosphor-coated imaging plates.

Digital radiography has several important benefits as images can be enhanced and magnified for viewing and interpretation of findings.

Students learn blueprint reading, basic metallurgy, measurement, and proper use of equipment used in the various NDT testing processes. Mid-level mathematics, communication skills, writing, and understanding codes & procedures, materials composure, and basic theories of economics are also integrated into the program. SAU Tech created this program emphasis in response to requests from industries such as Aerojet Rocketdyne, Lockheed Martin Missiles and Fire Control, Armtec Defense and others.

SAU Tech Chancellor, Dr. Jason Morrison said, “It’s a way to test for defects, be it a crack or corrosion without causing harm to what you are x-raying. For our purpose out in the park , its rocket motors, equipment, parts, mechanism, but it can be used in the oil industry, the aviation industry . It’s a very broad kind of field.”

While nondestructive testing has been available for the workforce at Highland Park for almost a year, now students of SAU Tech will get a chance to study.

Morrison said, “We started work force training last summer. We’ve had a lot of strong support as far as the workforce training side and a lot of students started contacting us about degree opportunities. With students contacting us and expressing interest we explored the option of creating an academic degree program. It’s an option under our Associate of Applied science and industrial science.

What that does is open open up financial This program does fall under the workforce 2000 grant and general student aid.”

Morrison said there was a lot interest in the program with SAU Tech students feeling “like this degree is going to give them a leg up in getting a position in the park.”

Even so, Karen House Workforce Initiative Coordinator says the program is still relatively unknown.

House said, “A company called the other day and said, ‘I didn’t know you offered it.’ We’ve had open houses and put it everywhere you can put it.”

According to information provided by SAU Tech the median wages in 2017 were $29.92 hourly and $62,230 annually. The projected growth in the field to 2026 is estimated to be from 5 to 9 percent with 80,800 jobs projected for the field.

Classes are taught by Jerimie Butler, an Aerojet Rocketdyne employee with 20 years of experience in the field of nondestructive testing.

Morrison said, “To have someone that has the knowledge and then can relate that to the students is an assett. He can actually teach it and provide it in a manner that they can grow and develop.”

House said, “He’s in that field, He’s a supervisor, so he kind of knows what he wants to see out of an employee or student. Hes always had really small classes, so he’s been able to do that one on one with them. So we’ve always tried to keep it around eight.”

Safety is paramount when working with dangerous x-rays. The first lessons are in radiation safety which SAU Tech’s course catalog says, “ promotes radiation safety in the industrial radiography industry. This course is intended to promote and preserve the professional integrity of industrial radiography radiation safety in the joint interests of those personnel and the public at large.”

Other classes include:

Radiographic Testing

Level I

This course is devised to give an introductory study of the processes of radiography. It provides the indepth study and hands-on experience needed to prepare the student for a position in the field of radiography. This course is designed to meet certain NDT Level I requirements.

Radiographic Testing

Level II

This course is devised to give a detailed study of the processes of radiography. It provides the in-depth study and hands-on experience needed to prepare the student for a position in the field of radiography. This course is designed to meet certain NDT Level II requirements.

Magnetic Particle/Liquid Penetrant Testing

This course is designed to give the student a complete introduction through hands-on experience in the magnetic particle and liquid penetrant methods within the field of nondestructive testing. This course is designed to meet certain NDT Level II.

Ultrasonic Testing I

This is devised to give the student a complete introduction through hands-on experience in the ultrasonic method within the field of nondestructive testing.

While in the x-ray lab, all students wear a detection badge which changes color when exposed to x-rays. The practical work is done with a lead cabinet donated by Lockheed Martin. Aerojet Rocketdyne is planning on donating a more up to date x-ray machine.