When John Dawson III was a young child, he knew what he wanted to do with his life.

"When I was six years old, I told my grandmother that when I grew up I wanted to to drive a a pickup, I wanted to chew tobacco and I wanted to spot pulpwood for a living," he said.

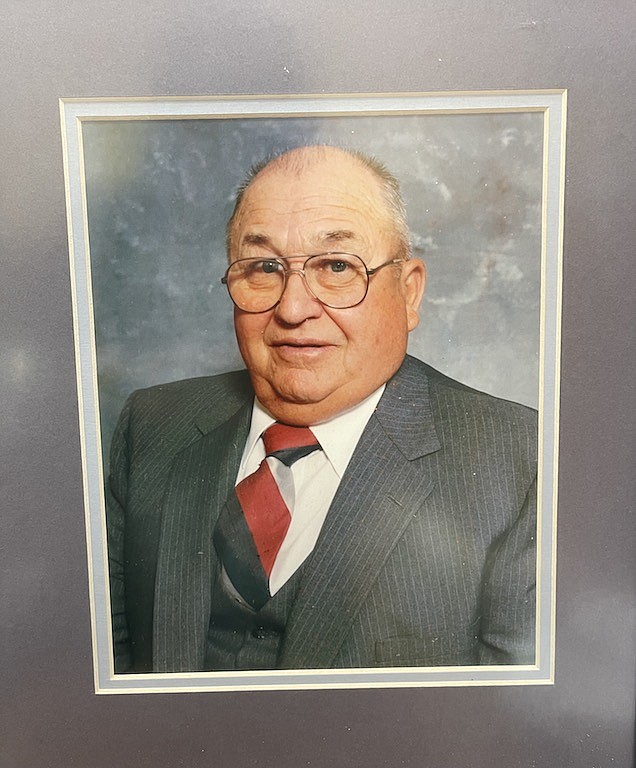

These early career goals probably didn't come as a shock to his grandmother. Forestry was in Dawson's blood. His father, John Dawson Jr, was the owner of Arkansas Pulpwood, a company that Dawson III co-owns today and runs with his sisters, Jane Marie Reeves and Martha Dawson.

"There was a lot of times, as we were growing up as little children, that our father would be gone before we got up, and then he wouldn't get home until sometimes 9 or 9:30 at night. We would all already be asleep and in bed when he got home. But he loved what he did and he believed in what he did."

Dawson said, "Our father John Dawson Jr. began what is now, Arkansas Pulpwood in 1973 and our father worked. He was a UAM forestry graduate served in the army and came back to work here in the late 60s and began his career with Bearden Lumber Company with John Ed Anthony and he worked there for a couple of years. And then he went to work in the private sector. He went to work for a guy named Doyle Harvey, and Doyle actually had Arkansas Pulpwood (Then known as Doyle Harvey Pulpwood) and this was back in the late 60s."

Dawson said the timber industry of yesteryear was much different than the industry today, which hauls logs around the area.

"Timber in rural South Arkansas was for the most part was all cut up into six foot billets and hauled to the local paper mill."

One day, Dawson Jr, was offered a chance to take over the business from Harvey.

Dawson III, said, "He worked for Doyle for about two years and in 1971 Mr. Harvey called our father to the breakfast table early one morning and said he was ready to sell out and wanted to sell the he business to our father, John Dawson Jr. In 1971 that cost was $10,000."

Dawson Jr, went to his father John Dawson Sr, who would later become a state senator in Camden and had a prosperous insurance agency, because the bank would only authorize a loan with his father as a cosigner.

Dawson III said, "Our Father didn't even have status enough to go get $10,000 in 1971 and and our grandfather said 'You got to be crazy.' He wasn't going to do that."

Dawson Jr returned to work for Harvey, but two years later was once again offered the opportunity to purchase Doyle Harvey Pulpwood, this time at a remarkably increased price.

"Mr. Harvey called him back to the breakfast table early one morning and said, 'This is your last opportunity. And today I want a hundred thousand dollars.' In 1973, that was a lot of money."

Dawson Jr, once again needed a co-signer but instead of asking his father, he went to ask his father-in-law, who owned the Lincoln Mercury Dealership in Camden.

His father-in-law agreed and Dawson Jr was the new owner of what he would christen Arkansas Pulpwood Company.

"By 1974, Dad had a hundred and fifteen billet trucks running in South Arkansas," Dawson said.

Around this time, the nature of forestry was changing in South Arkansas; instead of the small billets of the past, whole logs would now be shipped to mills. Dawson Jr purchased new equipment such as a skidder, loader and more modern sawing equipment to replace the teams of chainsaws that traditionally felled trees in South Arkansas.

Dawson Jr also found a niche in the timber market by cutting and helping private landowners sell their timber, since the majority of paper mills did not buy from the public.

"Dad was one of the first, if not the first, to kind of invent the modern day timber industry for private landowners," he said."

Dawson III came to work for his father in 1994, but the relationship, by Dawson's own admission, was an uneasy one at first.

He said, "In 1984 my mother and father divorced and there was a about six or eight years in there that my father and I didn't have a real good relationship due to that, but once I moved back here and went to work full time in '94, we began to see eye to eye and we ended up being best friends and hunting partners. We did just about everything, except on Sunday mornings we'd go to church in different places. I always told people that that Sunday was our one day of the week that we needed time away from each other."

When the International Paper Mill closed in Camden in 2001, the whole town was affected and Arkansas Pulpwood was no exception.

Dawson said, "Our base work area was was within 60 miles of Camden for a long time and hauling back to the Camden Mill. A lot of our workers lived in and around Camden. So hauling back to the Camden Mill was like getting home in the evening time on the last load. They would be close to the house. So when the Camden Mills shut down, all of a sudden we started having to deliver to other facilities, such as the IP paper mill in Domino, Texas which is a hundred miles away, dealing with Pine Bluff paper mill, which is 75 miles away. So our transportation cost over the years have just skyrocketed."

Another challenge Arkansas Pulpwood is facing is the nature of how trees are grown, Dawson explained.

"We began mechanically site preparing the site for replanting and this is much like you would see in a in a person's garden where we go in and till the hard pan and established a place to plant upon the furrows on the beds. We plant those seedlings up on those beds. And by tilling that subset, that hard pan, that subsoil, we bust that that hard pan open and it allows the root system to get established quicker, which allows the tree to start growing up faster. Over the years we've evolved that to where we confidently can say that we can grow timber faster than anybody in South Arkansas."

The downside to this is marketability, Dawson said,

"Over the years we've lost somewhere around 18 sawmills when the housing crashed happened in 2008. And we've lost six paper mills, so along with growing this timber fast -- now we have the capability we can grow it faster than anybody in the state -- but then we can not sell it faster than anybody in the state, too. So we're outgrowing, as a state, we're outgrowing our sales from timber harvest versus growth by 100,000 tons a year."

Dawson said that even though harvesting timber is at a high rate, the timber industry self regulates with best business practices in the form of stewardship and land conservation.

"We have business practices in place that are that are industry-wide. We're a self-regulated industry, and we volunteered 25 or 30 years ago to become self-regulated to try to keep the government out of it. So we, the state, has implemented what they call BMPS -- best management practices -- for logging and the Arkansas Forestry Commission does a good job of keeping up with those, again, suggestions. They're not laws. They're guidelines."

He continued, "We try to do what we call Streamside management zones, SMS, where we protect water quality, we protect from erosion. And it provides a wildlife strip. In a lot of times leaves that hardwood up and down where the hardwood grows in lower wetter areas."

In it's 50th year of existence, Arkansa Pulpwood is preparing for a future in South Arkansas the way they always have, with family, as John Dawson IV has recently joined on with the company as a third generation to take to the woods.

The company also plans to celebrate it's 50th year on June 2, from 11:30 a.m. to 5 p.m. at it's location on 1575 Cash Road.